Thank you for visiting my theme! Replace this with your message to visitors.

PRODUCTS

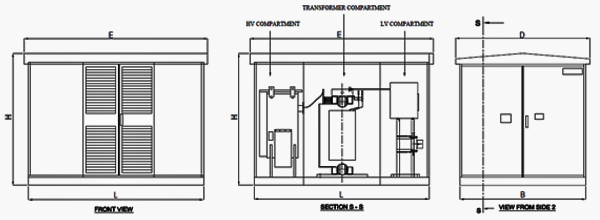

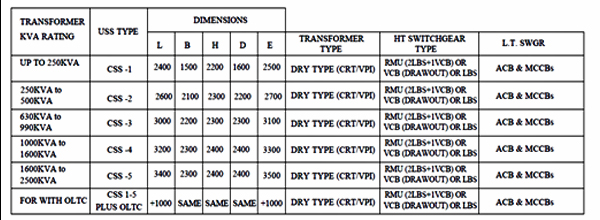

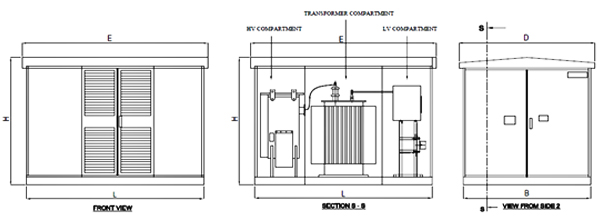

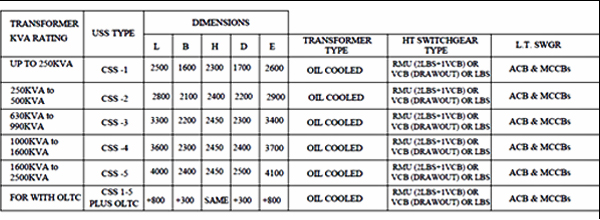

Compact Substation essentially consists of an assembly of the following on common base.

| HV COMPARTMENT | TRANSFORMER COMPARTMENT | LV COMPARTMENT |

|---|---|---|

| LOAD BREAK SWITCH(LBS) OR RING MAIN UNIT (RMU) OR VACUUM CIRCUIT BREAKER (VCB) | OIL FILLED TRANSFORMER OR DRY TYPE (VPI/CAST RESIN) TRANSFORMER | ACB / MCCB WITH BUILT IN OVER CURRENT, SHORT CIRCUIT AND EARTH FAULT PROTECTION |

| COMPARTMENT FITTED WITH LOCKABLE SWING HANDLE AND THREE POINT LATCH | COMPARTMENT FITTED WITH LOCKABLE SWING HANDLE AND THREE POINT LATCH | COMPARTMENT FITTED WITH LOCKABLE SWING HANDLE AND THREE POINT LATCH |

| POWER FUSES AND / OR SHUNT TRIP COIL | INTERNAL LIGHTING | TVM,METERING(VOLTMETER AND AMMETER WITH SELECTOR SWITCHES) |

| DOOR LIMIT SWITCH | CABLE / BUS BARS FOR HV AND LV CIRCUIT BREAKER CONNECTION | ELECTRICAL INDICATORS AND INTERNAL LIGHTING |

| WTI (ANALOG / DIGITAL)& OTI | LOUVERED COVERS | SPACE HEATER WITH THERMOSTAT CONTROL |

| AUXILIARY SUPPLY PLUG AND SOCKET | ||

| OPTIONAL ACCESSORIES | ||

| VARIOUS RELAY PROTECTIONS | OFF CIRCIUT TAP CHANGER (OCTC) / ON LOAD TAP CHANGER (OLTC | 'N' NO. OF DISTRIBUTION BREAKERS (ACB/MCCB) |

| HT METERING | APFC PANEL / CAPACITOR BANKS | |

| SURGE / LIGHTNING ARRESTORS | SYNCHRONISATION PANEL |

| RATED VOLTAGE (kV) | 3.6 | 7.2 | 12 | 24 | 36 |

|---|---|---|---|---|---|

| RATED INSULATION LEVEL (kVrms/kVp) | 10/40 | 20/60 | 28/75 | 50/125 | 70/170 |

| RATED FREQUENCY (Hz) | 50 | ||||

| OIL FILLED TRANSFORMER HV VOLTAGE LV VOLTAGE FREQUENCY |

25/40/63/100/250/315/400/500/630/750 /1000/1250/1600/2000/2500kVA 3.3/6.6/11/22/33kV 433V,3PHASE Or custom built 50Hz | ||||

| DRY TYPE – VPI / CAST RESIN TRANSFORMER HV VOLTAGE LV VOLTAGE FREQUENCY |

25/40/63/100/250/315/400/500/630/750 /1000/1250/1600/2000/2500kVA 3.3/6.6/11/22/33kV 433V,3PHASE Or custom built 50Hz | ||||

| RING MAIN UNIT (RMU) | 11/22/33kV,3 PHASE,50HZ SWITCH – 630/1250A,21/26.3KA,3PHASE BREAKER – 200/630A,21/26.3KA,3PHASE | ||||

| VACUUM CIRCUIT BREAKERS (VCB) | 11/22/33kV,3 PHASE,50HZ 200/400/630/1250A,18.4/21/26.3KA,3PHASE | ||||

| LOAD BREAK SWITCH (LBS) | 11/22/33kV,400/630A,3 POLE, AIR BREAK WITH FUSE ARRANGEMENT AND SHUNT TRIP COIL 230V AC | ||||

| TRANSFORMER | 3.3/6.6/11/22/33kV / 433V 3Phase,50HZ WITH OFF CIRCUIT TAP CHANGER / ON LOAD TAP CHANGER, Dyn11 | ||||

| LV BREAKER INCOMER MAIN BREAKER – DISTRIBUTION ACB'S / MCCB 'S | 433V,3 PHASE,50Hz 100A TO 4000A, 65KA UP TO 10NO'S ACB'S / MCCB 'S |

We have sophisticated modern machineries in our production lineup for manufacturing good quality products

Some of the machines and other tools made available in this unit are:

| Hydraulic Bus bar Bending Machine | Press | Grinding machine | Shearing Machine | Drilling Machine | Winding Machine HV – 2Nos | Winding Machine LV – 1No | CO2/Arc Welding machine | A frame | Oil Filtration Machine | Oven |

|---|

Some of the Testing Equipmentsfor Routine testing of the products as per relevant IS / IEC standards are:

| Testing Equipment | HV Kit | Dimmer | Motors | Insulation Resistance Kit | Contact Resistance Kit | Current Injection Kit | Voltage Ratio Kit | Power Analyser | Winding resistance meter | Oil BDV Kit | Pressure gauge |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tests | Power frequency / High Voltage test | NLL, LL, %Z | DVDF | IR test | Contact resistance test | CT, Relay testing | Ratio test | NLL, LL, %Z | Winding Resistance test | Oil BDV test | Pressure test |

Design conforms to International Electro technical Commission (IEC)62271-202 standard.

Design conforms to International Electro technical Commission (IEC)62271-202 standard. Compact substation construction saves floor space (Up to 70% in comparison with conventional systems).

Compact substation construction saves floor space (Up to 70% in comparison with conventional systems). Designed to withstand electrical impulses, thermal & dynamic stresses.

Designed to withstand electrical impulses, thermal & dynamic stresses. Equipments mounted on common ISMC channel base with fabricated CRCA sheet steel. Easy to lift both from top and bottom of CSS.

Equipments mounted on common ISMC channel base with fabricated CRCA sheet steel. Easy to lift both from top and bottom of CSS. Easy installation / Maintenance of Transformer – Transformer can be installed / accessed from roof top or hinged doors / side panels.

Easy installation / Maintenance of Transformer – Transformer can be installed / accessed from roof top or hinged doors / side panels. Safety – Duct and Pressure relief flaps provided for operator and public safety from internal arc.

Safety – Duct and Pressure relief flaps provided for operator and public safety from internal arc. Meets IP55/IP54& IP23 degree of protection.

Meets IP55/IP54& IP23 degree of protection. Designed to withstand electrical impulses, thermal & dynamic stresses.

Designed to withstand electrical impulses, thermal & dynamic stresses. Cost Effective – Costly cabling eliminated. Reduced civil work. Factory assembled & Factory tested, thus reducing the work to be done at site.

Cost Effective – Costly cabling eliminated. Reduced civil work. Factory assembled & Factory tested, thus reducing the work to be done at site. Enclosure is Aesthetically pleasing.

Enclosure is Aesthetically pleasing. Protection from Unauthorized access & Environmental Hazards.

Protection from Unauthorized access & Environmental Hazards. One point contact – Easy specification.

One point contact – Easy specification. Low power loss and Low noise transformer.

Low power loss and Low noise transformer. Short delivery & ready for commissioning.

Short delivery & ready for commissioning. Custom built – variety of choices for MV/LV switchgears, no. of feeders to suit user requirements.

Custom built – variety of choices for MV/LV switchgears, no. of feeders to suit user requirements. Modern manufacturing techniques ensure cost effectiveness, reliability & long trouble free performance, and better safety.

Modern manufacturing techniques ensure cost effectiveness, reliability & long trouble free performance, and better safety. Replacement for conventional pole mounted transformers

Replacement for conventional pole mounted transformers Residential Complexes / Apartments

Residential Complexes / Apartments Commercial Buildings

Commercial Buildings Industries

Industries Power Distribution

Power Distribution Hospitals

Hospitals Software Parks

Software Parks Development Projects

Development Projects Construction Sites

Construction Sites Solar Power Generation

Solar Power Generation

One of our best

One of our best

One of our best

One of our best

One of our best

One of our best

One of our best

One of our best

One of our best

One of our best